Le Toit Terrasse en Bac Acier : Une Solution Moderne et Pratique

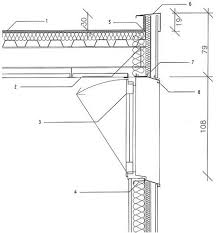

Article sur le Toit Terrasse en Bac Acier Toit Terrasse en Bac Acier : Une Solution Moderne et Pratique Le toit terrasse en bac acier est une option de plus en plus populaire pour les

Article sur le Toit Terrasse en Bac Acier Toit Terrasse en Bac Acier : Une Solution Moderne et Pratique Le toit terrasse en bac acier est une option de plus en plus populaire pour les

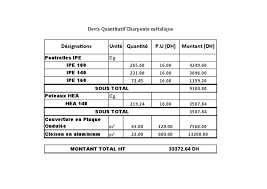

Devis Charpente Devis Charpente : Comprendre l’Importance de l’Estimation des Coûts pour Votre Projet de Construction Lorsque vous envisagez de construire ou de rénover une maison, la charpente est l’un des éléments essentiels à prendre

Article sur la toiture en bac acier imitation tuile Toiture en Bac Acier Imitation Tuile : Alliance de Modernité et Tradition La toiture en bac acier imitation tuile est de plus en plus populaire pour

Article sur la toiture La Toiture : Un Élément Clé de Votre Maison La toiture est l’un des éléments les plus importants de toute construction. Elle protège votre maison des intempéries, des variations de température

Maisons Contemporaines : L’Art de Vivre Moderne Maisons Contemporaines : L’Art de Vivre Moderne Les maisons contemporaines sont devenues une tendance majeure dans le domaine de l’architecture résidentielle. Avec leur design avant-gardiste, leur utilisation innovante

Toit Cabane Bois : Un Charme Rustique et Authentique Les toits de cabanes en bois ont un charme indéniable qui évoque la simplicité, l’authenticité et la chaleur. Que ce soit pour une cabane de jardin,

Extension Bois Toit Plat Extension Bois Toit Plat : Une Solution Moderne et Élégante L’extension bois avec toit plat est devenue une option populaire pour ceux qui cherchent à agrandir leur espace de vie de

Travaux de Toiture : Tout ce que Vous Devez Savoir La toiture est l’un des éléments les plus importants de toute construction. Elle protège votre maison contre les intempéries, assure son isolation et contribue à

Extension de Toit – Tout ce que vous devez savoir Extension de Toit – Tout ce que vous devez savoir L’extension de toit est une solution populaire pour agrandir l’espace habitable d’une maison tout en

Le Toit en Acier : Une Option Moderne et Durable Le toit en acier est devenu une option de plus en plus populaire pour les propriétaires cherchant un matériau de couverture moderne et durable. Connu