Extension avec Toit Plat en Béton : Modernité et Durabilité assurées

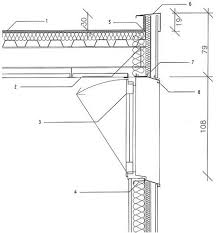

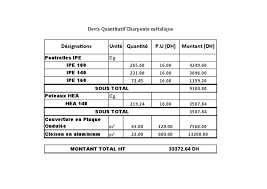

Extension Toit Plat en Béton Extension Toit Plat en Béton L’extension d’une maison avec un toit plat en béton est une option de plus en plus populaire pour agrandir l’espace habitable d’une maison tout en